What is Ripstop?

Share

Ripstop fabrics are a modern marvel in the world of textiles, offering unparalleled durability and resistance to tearing.

Originally developed for military use, ripstop has found its way into various applications, from outdoor gear to high-fashion items.

In this comprehensive guide, we will explore the ins and outs of ripstop fabric, understanding its unique properties, manufacturing process, and diverse uses.

Understanding Ripstop Fabric

The Basics of Ripstop

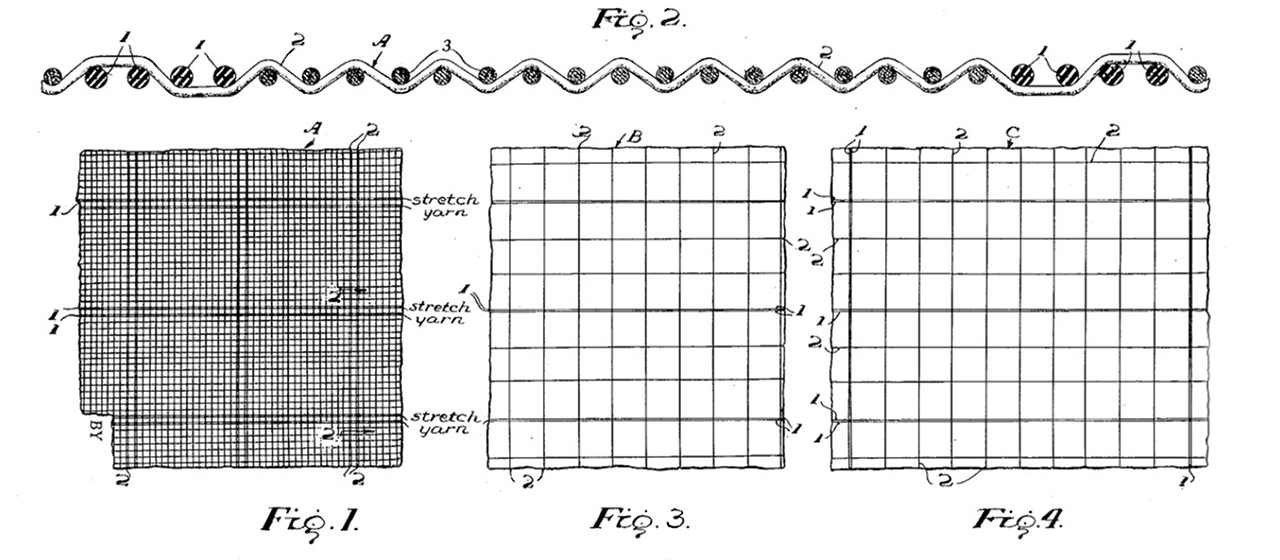

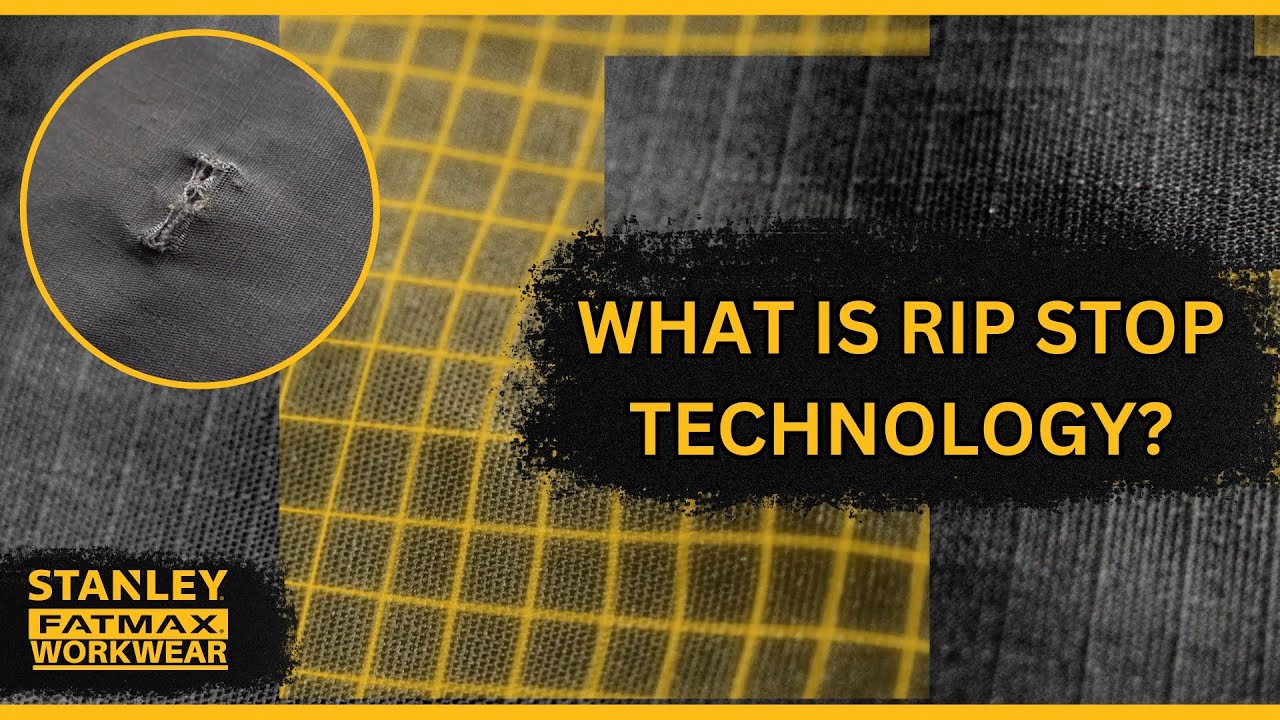

Ripstop fabric is a lightweight, durable material characterized by its reinforcing technique.

This technique involves a special reinforcing technique, usually a crosshatch pattern, woven into the fabric at regular intervals.

This structure prevents tears and rips from spreading, thereby enhancing the fabric's overall durability.

Materials and Weaving Techniques

Ripstop can be made from various materials, including nylon, polyester, and cotton.

The choice of material affects the fabric's characteristics, such as weight, breathability, and water resistance.

The weaving process of ripstop is unique and integral to its strength.

Small, thicker threads are interwoven at regular intervals into a finer fabric, creating the distinctive crosshatch pattern.

The Evolution of Ripstop

Historical Development

Ripstop was initially developed during World War II as a material for military parachutes.

Its lightweight and strong properties made it ideal for this purpose. Over time, its use expanded beyond the military, gaining popularity in various civilian applications.

Technological Advancements

With advancements in textile technology, ripstop fabrics have evolved significantly.

Today’s ripstop fabrics may include coatings or treatments for enhanced water resistance, UV protection, or flame retardancy, making them more versatile than ever.

Applications of Ripstop

Outdoor and Sporting Gear

Ripstop's durability and lightweight nature make it ideal for outdoor and sporting gear.

It's commonly used in the manufacturing of tents, sleeping bags, backpacks, and lightweight outdoor clothing.

Its resistance to tearing is particularly valuable in environments where fabric durability is crucial.

Fashion Industry

The fashion industry has embraced ripstop for its unique texture and durability.

It's used in various garments, including jackets, pants, and accessories, often for a stylish yet functional appeal.

Other Uses

Beyond clothing and outdoor gear, ripstop finds applications in various fields such as aeronautics (for parachutes and hot air balloons), sails for sailboats, and even in some high-strength industrial applications.

Advantages of Ripstop Fabric

Durability and Strength

The primary advantage of ripstop is its resistance to tearing and ripping. This makes it an excellent choice for applications where fabric strength is crucial.

Lightweight and Comfortable

Despite its strength, ripstop is surprisingly lightweight. This makes it comfortable to wear and easy to pack, an essential factor for outdoor enthusiasts and travelers.

Versatility

Ripstop’s versatility allows it to be used in a wide range of products, from technical outdoor gear to everyday fashion items.

Its adaptability to different treatments and coatings also enhances its functionality in various environments.

Caring for Ripstop Fabric

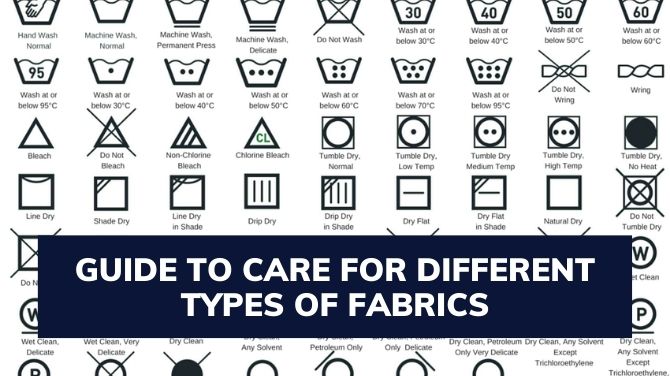

Washing and Maintenance

Ripstop is generally low-maintenance. However, it's essential to follow care instructions, typically involving gentle washing and avoiding high heat, to maintain the fabric's integrity and prolong its life.

Repairing Ripstop

One of the benefits of ripstop is that small tears or rips can be easily repaired without compromising the fabric's overall strength and appearance.

The Future of Ripstop

Innovations and Trends

The future of ripstop fabric looks promising with ongoing innovations.

Researchers and manufacturers are continuously exploring new materials and weaving techniques to enhance its properties, such as stretchability and environmental sustainability.

Expanding Applications

As technology advances, the potential applications for ripstop fabric continue to expand.

Its use in emerging fields such as eco-friendly products and high-performance sports equipment is just the beginning.

Conclusion

Ripstop fabric represents a remarkable blend of strength, durability, and lightweight convenience.

Its evolution from military parachutes to a staple in various industries underscores its versatility and effectiveness.

As we continue to see innovations in textile technology, ripstop fabric will undoubtedly play a significant role in shaping the future of durable and functional textiles.